- 20 September, 2022

- Posted by: Tim Hodgetts

- Category: Blog, world news

As we look back on 70 years of Elizabeth II’s reign it is evident that our industry went through a revolution. Chicken went from being a delicacy to being the cheapest meat on the market. Poultry business evolves and creates new challenges and opportunities. But will it have the support of Britain’s new monarch?

The end of an epoch

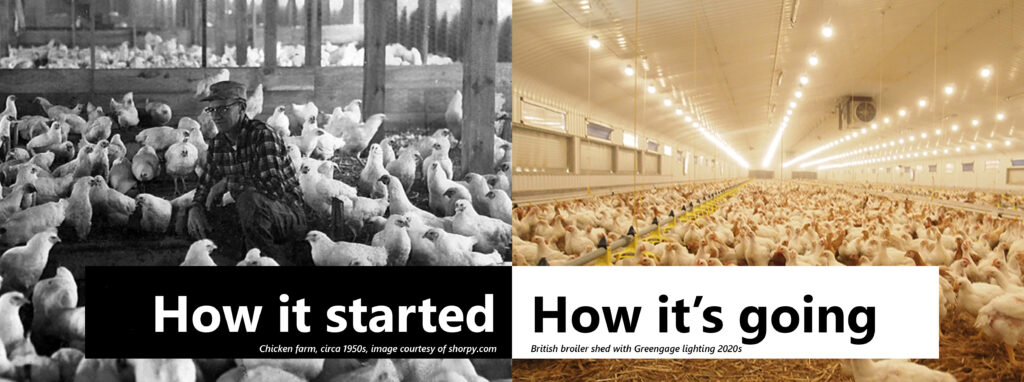

As I write this the UK is mourning our longest-serving monarch Elizabeth II. Her reign has seen cataclysmic events and seismic changes to the world as a whole and Britain in particular. Due to the often-hereditary nature of the farming business I think farmers can appreciate the changes even more than the regular citizen. I know for certain that the industry my grandfather worked in was very different from the one I see now. When Elizabeth ascended the throne in 1952, chicken was a luxury food eaten on special occasions and on vacation, the national per capita consumption was estimated at 2.7 kg (6lb) a year. Most poultry was grown for eggs.

Compare this with today – chicken is the cheapest source of meat; it caught up with beef and pork and surpassed both in consumption per capita which is more than 20kg a year. In 70 years, poultry production moved indoors, and the structure of the poultry shed has gone through rapid evolution. We learned to insulate and ventilate the shed, we learned to feed our chickens the right amount and composition of feed, we switched to new breeds that were bred specifically for high intensity production. In the last few decades, we saw the battle for flock uniformity and optimal feed conversion ratio go to unimaginable heights with the aid of modern digital technology and ingenious engineering solutions.

Moving poultry production indoors

One of the key things that allowed us to take our chicken production fully indoors was lighting. All living beings need water, food and light. Feed and water were more or less available year-round, but lighting was not, resulting in very heavy seasonality; artificial lighting was the solution that helped us leave seasonality behind and create this stable year-round productive industry that is poultry.

Reinventing poultry lighting

Breeding efficient breeds and making efficient feeds had been the main focus of the industry for 50 years, but in the 2000s when the gains on those has all but capped the next leap was providing chickens with conditions that promoted natural behaviours and alleviated stress – it was time to reinvent poultry lighting. The very thing that allowed us to switch to fully indoor production was now slowing the industry down by being not up to the standard of the incredible feed, breed, medication and sanitization that were widely adopted by the industry.

We created our company to address this very issue and invented a poultry lighting system that was sophisticated and easy to use. We designed it with our parents in mind, who were all still running farms at that point. “Make a product that is easy to use but also provides the farmer with immediate benefits and significantly boosts productivity” and we succeeded at that. In the past decade the industry’s productivity was the highest it has even been, but margins kept shrinking and the market drive to supply high quality cheap meat was ever increasing.

New horizons of precision livestock farming

This brings us to the challenge of today – fine tuning the farm, ironing out all the kinks. To do that, farms need more information on how their flock is faring – detailed graphs, correlation and causation. It all gets very clinical and scientific when you push the boundaries of what is possible. We developed poultry sensors that analyse the conditions in the shed every 15 minutes and give live 24/7 status updates in a user-friendly app. We manage to decrease mortality by 0.7-1%, we help achieve a more optimal FCR and better flock uniformity, we aid scheme compliance. These are marginal gains, but they can be the difference between profit and loss in this field. Agritech will continue to evolve, for certain, we’ve already seen robot stockmen, AI powered analytics tools and so much more, one can only guess what kind of technology awaits us in the following decades.

The future of British farming

One thing I can say for certain that in the trials and tribulations of the past century farming went from a very respectable profession to one that is regularly assaulted by politicians, media and consumers even though the modern farmer is doing so much more and working to a much higher standard than our predecessors. We still take immense pride in what we do, but more and more we find that our consumer doesn’t share the sentiment. The Queen was our one constant supporter, she was a champion of the rural way of life, a patron of many an agricultural organization, a consumer that famously backed British produce. Our new King Charles III has long talked about increasing food security and making Britain independent from food imports. We can only hope that he will take an active role in supporting British farming and farmers, because it feels like we will need all the support we can get.