- 18 August, 2023

- Posted by: Marketing Manager

- Category: Blog

Modernising the Future of Poultry Farming with Greengage

Farming has always been an amalgamation of tradition and innovation. With each passing decade, it has embraced the benefits of technology to enhance productivity, maintain animal welfare, and increase profitability. Greengage, with its keen understanding of this blend, is pushing the boundaries by incorporating advanced tech solutions into the heart of poultry farming.

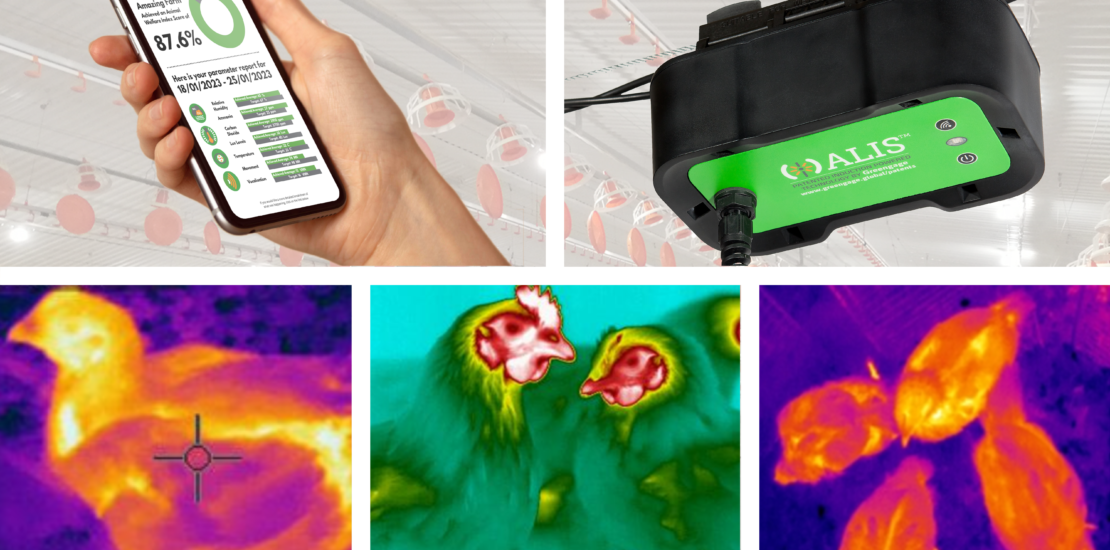

Our journey began with the ALIS lighting solutions, meticulously designed to create the perfect conditions for your livestock and a robust lasting solution for your shed. But as the saying goes, “resting on one’s laurels” is not the Greengage way. So, here we present our newest innovation: the ALIS PULSE sensors complemented with an all-encompassing data platform subscription.

A New Age of Poultry Farming

Poultry units are more than just shelters from the dangers of the outside world. They are well-calibrated environments where multiple factors such as temperature, humidity, food source, water source, lighting programs and biosecurity are adjusted to ensure optimal growth and wellbeing for the livestock. Integrating ALIS PULSE sensors to aid precision takes farming from guesswork to informed decision-making.

While data forms the foundation of our innovation, Greengage recognizes that raw numbers without appropriate context are not of much use to the customer. Our platform offers much more than just metrics. It provides actionable insights, recommending necessary interventions based on the readings of:

- Temperature

- Lux levels

- Humidity

- CO2

- NH3

- Acoustic measure of distress signals

- Thermal video analytics capturing movement patterns and clustering

Basis of Our Insights

Greengage’s insights are rooted in science. Derived from extensive scientific studies and a massive database of anonymized information, our platform tells you not just what is happening but explains the reasons behind it and suggests actionable measures. With us, data transforms from mere numbers to a potent tool, steering your farming practices towards enhanced animal welfare, boosted productivity, and increased profitability.

Understanding the Tech Behind ALIS PULSE Sensors: An Insight into CO2 and NH3 Sensing

Greengage’s commitment to accuracy and innovation shines through in our choice of devices for gas sensing. Our sensors, equipped with industry-standard NDIR and Electrochemical technologies, offer flexibility, durability, and precision. Particularly for the volatile ammonia gas, calibration remains pivotal, especially given its corrosive nature. Farmers maintain stringent adherence to UK and EU guidelines, ensuring ammonia levels remain between 0ppm to a maximum of 20ppm, we make sure that they are constantly aware of ammonia levels in their sheds. Our targeted accuracy revolves around ±5% of the measured value or ±2 ppm.

While current metrics don’t compare gas values to ambient conditions, it’s noteworthy that ambient ammonia is in the parts per billion range, and ambient CO2 is around 400 ppm. Our primary focus is timely alerts for significant deviations against set thresholds and the duration taken to revert to acceptable levels post intervention.

Moreover, the potential addition of a Methane (CH4) sensor is on our future roadmap. Such an addition could be useful in aiding farmers reduce methane emissions, optimising gut health in poultry and minimising methane production associated with fermentation.

Data Collection and Transmission

The potency of any tech solution lies in its effective data handling. The ALIS PULSE Sensors, designed for diverse livestock environments, prioritize frequency and accuracy in data collection. These features ensure prompt actions, either manual or automated. One of the notable challenges is maintaining data integrity in remote locations, especially during connectivity issues. Greengage’s solution ensures local data storage during connectivity lapses and seamlessly transitions to cloud-based access and analytics upon reconnection.

The Importance of Ammonia Sensing

Ammonia’s influence on livestock health cannot be overstated. Elevated ammonia levels can detrimentally impact the respiratory system, escalate the risk of infections, and trigger stress in animals. Such stress manifests in various ways, from reduced feed intake and increased water consumption to altered behavioural patterns. Furthermore, heightened ammonia levels could be indicative of underlying health challenges in poultry. For instance, a flock with elevated ammonia might signify the presence of distressed birds producing excess waste and uric acid, leading to ammonia buildup. The consequences of unchecked ammonia levels extend to stunted growth rates, reduced reproductive performance, and a decrease in production efficiency.

The ALIS PULSE Cluster Sensor: Revolutionising Poultry Movement Analysis

Greengage’s proprietary ALIS PULSE Cluster Sensor brings a paradigm shift in how poultry movement is analysed and understood. Utilising advanced thermal imaging technology combined with a proprietary algorithm, this sensor offers a profound insight into the activity within a shed, specifically focusing on movement uniformity. One of the significant advantages of the Cluster sensor is its ability to detect irregular movements indicative of stress and clustering behaviours.

While traditional sensors gauge ambient and gas parameters to assess poultry conditions, the Cluster Sensor provides an advantage by discerning distress even before such parameters exhibit notable changes. Consequently, it serves as an invaluable early warning system for stockmen. Before any significant impact on productivity occurs, stockmen can be prompted by the sensor to inspect the shed, identify potential issues, and intervene accordingly. By acting as a pre-emptive measure, the Cluster Sensor not only augments the wellbeing of the poultry but also optimizes productivity outcomes.

ALIS PULSE Chirpy Sensor: Deciphering Distress Through Sound

ALIS Chirpy is an embodiment of Greengage’s commitment to blend innovation with welfare in livestock management. Amongst Greengage’s suite of sensors, Chirpy stands out with its focus on acoustic detection within poultry sheds. This sensor has been meticulously developed after years of research, collaboration, and scientific studies, enabling it to discern specific chirps indicating stress in poultry.

The inspiration behind Chirpy is fascinating. Skilled stockmen, with their honed instincts, can often discern an anomaly in a shed just by the sounds or slight changes in behaviour. While technology cannot replicate the intuition of a stockman, Chirpy does the next best thing. It offers a persistent monitoring mechanism, operating tirelessly throughout the year. When it identifies abnormal stress levels in the chirps, an alert is dispatched to the farm manager, allowing for timely intervention.

But what do these sounds mean? Primarily, they signify stress. A poultry shed devoid of stress typically indicates higher productivity, better feed conversion ratio (FCR), and reduced mortality. Conversely, heightened stress levels can directly correlate with reduced productivity, negatively impacting profit margins.

Chirpy’s advanced algorithm adapts to the varying chirps produced by birds of different ages. It recognizes the distinct sounds made by a 1-day old chick as compared to a 37-day old bird and accurately identifies stress chirps across age groups.

In the broader scheme of livestock management, acoustic or sound sensors like Chirpy play a pivotal role in ensuring optimal productivity. They act as a preliminary warning system. Waiting for tangible indicators such as increased water consumption or spikes in humidity and temperature can sometimes be too late. Birds are exceptionally sensitive to their surroundings, and the earliest indication of their discomfort often manifests through their sounds. By addressing these early indicators, farmers can mitigate potential issues, maintaining flock uniformity and ensuring consistent productivity.

While Chirpy is tailored for poultry, Greengage acknowledges the unique challenges faced in different livestock environments. That’s why a counterpart called Grunty caters to pigs. Though the underlying principle remains the same, the algorithms are customized for each livestock type, offering tailored insights. For instance, in layers, Chirpy could provide an early alert to issues like red mites by detecting restless sounds during the night. Each type of production, be it layers, breeders, broilers, or swine, comes with its set of challenges, and Greengage’s sensor suite is equipped to address them efficiently.

Into the Future with Greengage

At Greengage, our vision for the future of ALIS PULSE Sensors extends far beyond mere data collection. Envision a poultry shed where every element works in harmony, orchestrated by a centralized intelligence system. That’s the promise of the ALIS PULSE Controller. As we move forward, our aim is to seamlessly integrate the ALIS PULSE Sensors within the very heart of the shed. This will not only allow for passive monitoring but also proactive adjustments. Instead of merely reporting on conditions such as humidity, light, or CO2 levels, the Controller will actively adjust lighting levels and ventilation in real-time, based on the data fed from our state-of-the-art sensors.

We are creating not leap but a revolution. By automating these critical elements, we anticipate enhanced poultry well-being, reduced stress levels, and an environment that is consistently optimised for growth and productivity. The blend of Greengage’s sophisticated technology with the innate wisdom of farming practices means farmers can look forward to a future where the shed itself becomes an ally, intuitively making decisions for the betterment of the livestock. With ALIS PULSE’s continuous evolution, the fusion of science and tradition has never looked more promising.