- 21 September, 2022

- Posted by: Tim Hodgetts

- Category: Blog, tips and know-how

If you are thinking of changing your poultry lighting system or switching from non-poultry-specific lighting to professional poultry lighting, here are some tips that may be of use. Today, with the spiking gas and electricity prices, switching from CFL to LED poultry lights is an excellent investment that is guaranteed to pay off in less than 6 months. But how do you choose the right option for you? Read more to find out!

Even lighting is key

Chickens, by nature, are afraid of predators; uneven lighting alerts chickens, causes them stress, increases their energy consumption, and compromises their health. Make sure that lighting is even on all surfaces of the shed. Recently implemented window size standards can affect the distribution of your flock by creating spots that are too bright and hot in an already lit shed. If you are running into this issue, contact your poultry lighting manufacturer. We consult our clients on this regularly and have come up with several solutions that work for them.

Image courtesy of Tajmia Loiacono (@tajmia) | Unsplash Photo Community and K. Mitch Hodge (@kmitchhodge) | Unsplash Photo Community

Non-flicker is the way

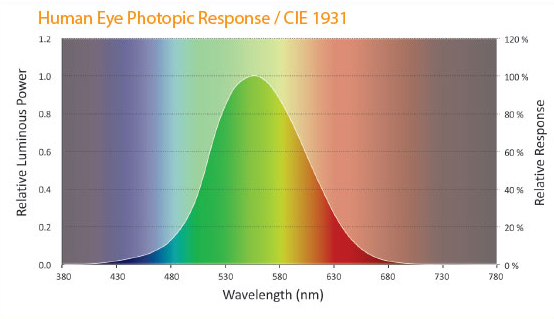

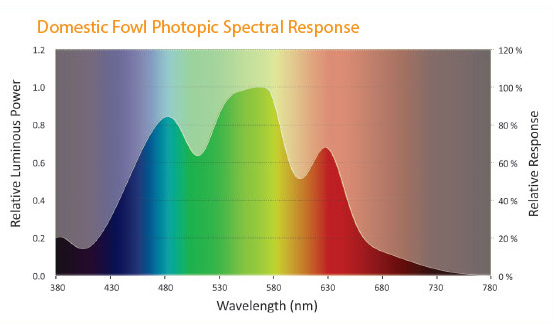

The human eye can’t detect the standard 50-60 Hz flicker in LED and fluorescent lamps. We don’t see the flicker, but our psyche suggests to us that something is wrong, and we always feel better after leaving a classroom or an office. So, the flicker does affect us, albeit only subconsciously. Chickens’ eyes, however, are very different; they can actually see the flicker. Imagine living your entire life in a room with a stroboscopic light and not being able to leave that room. That’s the reason flicker significantly decreases productivity and increases stress levels in poultry.

Non-flicker solutions include:

- DC setups (they don’t have flicker because the current is constant)

- AC setups with inbuilt capacitors to emulate a constant current

- AC setups with a frequency that is high enough to be undetectable by chicken eyesight (higher than 143 Hz)

Even though DC is the only truly constant source of light, it has a serious drawback – DC setups lose quite a lot of power and aren’t as energy-efficient as AC setups. Capacitors are like batteries, so they eventually fail, and the flicker gradually returns. Our own ALIS system is designed to have a higher frequency (50000 Hz as opposed to 50 Hz, so a 1000 times higher frequency than regular lights) and has a capacitor smoothing down the flicker even further, achieving a DC-like consistency of light without any of the DC energy losses.

When picking poultry lighting make sure to read the fine print!

Dimming is essential

The ability to fade in or fade out poultry lighting is vital to emulating natural day cycles. Humans don’t particularly appreciate being woken up with sudden glaring lights, and they can’t immediately fall asleep if you just turn the lights off. It will come as no surprise that chickens are even more sensitive to natural day cycles than humans. A slow fade in will allow them to experience a near-natural sunrise, waking them up gradually enough not to scare them, and a fade-out will slowly decrease their activity without triggering a stress response, allowing all the birds to fall asleep. Dimming is essential to promote natural behaviors, and you really can’t achieve the same productivity without it.

image courtesy of Wes Hicks (@sickhews) | Unsplash Photo Community and Patrick (@patuphotos) | Unsplash Photo Community

Made for chickens, not humans

For the best results, light your shed with professional poultry lighting. Quite a lot of modern lights can withstand the conditions of a farm and can be washed; they might even be dimmable and non-flicker, but as always, the devil is in the details. The light in a shed isn’t for humans, so buying a lamp that is balanced for human eyesight would not help chickens achieve their potential – for one, chickens see so many more colors than humans. Chicken eyesight covers a light spectrum that isn’t visible to humans at all. And perhaps even more shockingly – lighting is not just for the eyes. What? Yes! Light doesn’t just impact chickens’ vision, it is an integral part of their metabolism! Their comb absorbs certain light wavelengths and plays a key role in chicken metabolism. Who knew? (Well, honestly, we did.) The extent to which light requires to be balanced for chicken eyesight has been tested in many scientific studies, and this knowledge has been implemented in our products. The studies produced very graphic and conclusive evidence to the benefit of balancing lighting to chickens’ specific needs. The difference in lighting spectrum can result in a 15-20 percent difference in feather coverage alone! If that’s not a reason to invest in poultry-specific lighting, then what is?

Easy to maintain equipment

“Read the manual and maintain your equipment as instructed.” A tale as old as time, isn’t it? If one light fails and creates uneven lighting in a specific spot, replace the light as soon as possible. The idea might be simple, and yet the execution can be anything but. The one issue with traditional poultry lighting systems is the amount of fault lines in one strand of lights. Non-induction systems are essentially just a bigger, cooler version of Christmas lights – each light connects via wire to the central wire, creating a connection point where the wire can snap and fray. Each of these connection points is a fault line, so you have as many fault lines as lightbulbs. Sometimes repairs aren’t easy because the fault is somewhere in the wire, and it’s not easy to pinpoint where exactly that is. That was one of the reasons we chose to use induction for our system. After all, who wants to call an electrician for half a day to find out where something had snapped? Our system doesn’t compromise wire integrity, and replacements can be made by simply unclipping the broken light and clipping a new one on. Even a child could do it (if their hands were strong enough for the sturdy clip mechanism).

And as a side note: make sure to clean the lights between flocks. A light can’t be as bright if it is coated in dirt! Our own ALIS lights can withstand an industrial power washer (to be honest, we also rode one over in a utility tractor and it worked just fine).